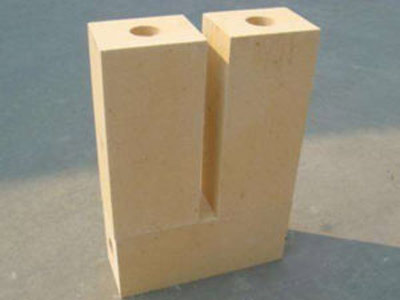

Zirconium bricks produced by our company is made of α-Al2O3, partially stabilized zirconia and zirconium corundum clinker. After mixing, molding and drying, it is fired at high temperature in the shuttle kiln. The zirconium brick product has the advantages of compact crystal structure, high bulk density, large volume, high mechanical strength at normal temperature and high temperature, good thermal shock stability, low reburning shrinkage and high temperature creep, and high chemical stability and resistance.

Characteristics such as alkaline medium erosion. Dense zircon bricks are mainly used in sodium-calcium glass kiln middle bricks, arched bricks, etc.; zirconium-containing bricks are mainly used in large glass kiln melting pools, picture tube kiln, regenerator partition wall bricks, and chemical and metallurgical industrial furnaces. The part that is affected by the solution. The dimensions, physical and chemical indicators and service life our products have reached or exceeded the level of similar products in domestic and abroad.

Pure zirconium bricks are widely used in non-metallic materials industry, petrochemical, steel smelting, military, electronics and other fields. For example: metallurgical industry silicon steel heating furnace lining, petroleum industry hydrogen furnace, gasification furnace high temperature equipment insulation lining, hard alloy intermediate frequency furnace insulation lining.

Technical Parameter of Zirconia Bricks:

| Zircon Bricks | ||||||

| Item/Index | ZR-30 | ZR-50 | ZR-55 | ZR-60 | ZR-62 | |

| Al2O3 % | 42 | 10 | 6 | 4 | – | |

| SiO2 | 20 | 34 | 35 | 30 | 34 | |

| ZrO2 | 30 | 50 | 55 | 60 | 62 | |

| Bulk Density (g/cm3) | ≥3.10 | ≥3.30 | ≥3.45 | ≥3.50 | ≥3.60 | |

| Apparent Porosity % | ≤21 | ≤20 | ≤20 | ≤21 | ≤20 | |

| Compressive Strength (kg/cm2) | ≥500 | ≥400 | ≥500 | ≥500 | ≥500 | |

| Refractoriness Under Load ℃ (T2) | >1500 | >1450 | >1500 | >1600 | >1550 | |

| Expansion at 1000℃ (%) | 0.6~0.8 | 0.4~0.6 | 0.4~0.6 | 0.4~0.6 | 0.4~0.6 | |

| Thermal Conductivity | 500℃ | 1.7 | 1.4 | 1.3 | 1.2 | 1.2 |

| 1000℃ | 1.8 | 1.6 | 1.5 | 1.5 | 1.5 | |

| Application | Glass Furnace | Nozzle Seat | Ladle | Ladle | Ladle Glass Furnace | |