Both corundum bricks and corundum mullite bricks are high-grade refractory materials with high-temperature compressive strength and excellent wear resistance. There are differences between the two in terms of composition and physical properties. Rongsheng Refractory Material Manufacturer is a refractory material manufacturer with rich production and sales experience. We provide refractory services globally. Product quality is reliable, after-sales service is guaranteed.

Corundum Brick and Corundum Mullite Brick

Corundum brick. Corundum bricks are mainly made of high-purity raw materials such as alumina and corundum and usually do not contain impurities such as free silicates. Among them, corundum is a mineral with high hardness and high density, which can form a hard crystal structure in the sintering process. As a result, the corundum brick has high compressive strength, wear resistance, and other properties.

Corundum mullite bricks. Corundum mullite bricks are mainly composed of corundum, mullite, alumina, and other raw materials. Among them, the functions of corundum and alumina are similar to those of corundum bricks, while mullite has a high melting point and refractory performance, and is a common component of high-quality refractory materials. The production process of corundum mullite bricks is more complicated than that of corundum bricks and requires multiple processes. From raw material preparation, and mixing to molding, sintering, etc. The whole process needs to control factors such as temperature, time, and pressure.

Physical properties of corundum bricks and corundum mullite bricks

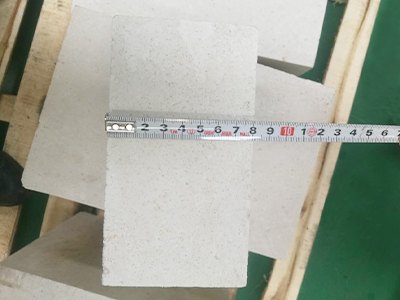

density. The density of corundum bricks is usually between 3.6-3.8g/cm³, while the density of corundum-mullite bricks is between 2.9-3.2g/cm³. Therefore, under the same volume, the corundum brick is heavier than the corundum mullite brick.

compressive strength. In high-temperature environments, both corundum brick and corundum mullite brick have high compressive strength. But in general, the compressive strength of corundum bricks is higher than that of corundum mullite bricks. Specifically, at a temperature of 1600°C, the compressive strength of corundum bricks can reach more than 120MPa, while the compressive strength of corundum-mullite bricks is around 80-90MPa.

abrasion resistance. Since the corundum brick contains a large amount of corundum crystals, its wear resistance is relatively excellent. Corundum bricks are widely used in the manufacture of wear-resistant lining boards, ceramic tiles, and other products. The corundum mullite brick also has high wear resistance, and due to the participation of mullite. Making it more corrosion-resistant, it can be used to make products such as acid and alkali-resistant bricks.

fire resistance. Corundum bricks and corundum mullite bricks have excellent refractory properties and are not prone to structural changes and shrinkage in high-temperature environments. The operating temperature range of the two is also very wide and can be used for a long time in a high-temperature environment of 1400°C-1800°C. Has extremely high stability and mechanical strength.

Thermal expansion coefficient. The coefficient of thermal expansion of corundum bricks and corundum mullite bricks is relatively small, especially at high temperatures. The thermal expansion coefficient of corundum bricks at 900°C is about 6.0×10^-6/°C, while that of corundum mullite bricks is about 7.0×10^-6/°C. Therefore, on some occasions that need to withstand high-temperature expansion stress, corundum bricks, and corundum mullite bricks are more suitable for use.

Application field of corundum brick and corundum mullite brick

Application fields of corundum bricks. Corundum bricks are widely used in various high-temperature industrial fields, such as metallurgy, building materials, chemicals, electric power, medicine, and other industries. Corundum bricks can be used to manufacture high-temperature furnaces, refractory linings, casting molds, electrolytic cell linings, etc. Its excellent properties make it an ideal refractory material.

Application fields of corundum mullite bricks. Corundum mullite bricks are widely used in the chemical industry, metallurgy, ceramics, and other fields. Among them, corundum mullite bricks have better acid corrosion resistance, especially in the steelmaking process, corundum mullite bricks can be used to make acid-resistant reactors. At the same time, corundum mullite bricks can also be used in high-temperature occasions such as making aluminum electrolytic cells.

RS Global Refractory Manufacturer

Both corundum bricks and corundum mullite bricks are high-grade refractory materials with excellent physical properties, but there are differences in their composition and physical properties. Corundum bricks are mainly composed of alumina and corundum and have high compressive strength and wear resistance. The corundum mullite brick is composed of corundum, mullite, alumina, and other raw materials, and its acid corrosion resistance is better. Both materials have a wide range of application fields, and it is necessary to choose the appropriate material according to specific production needs and environmental requirements. To purchase high-quality refractory brick products, please contact us. Get free samples, solutions, and quotes.