What are the names of refractory materials? The question itself is inaccurate. For example, there are many kinds of cars, such as cars, vans, off-road vehicles, trucks, and so on. And there are many cars with different brands or shapes in various fields, but they are collectively called cars. Various refractory bricks or castables are collectively referred to as refractory materials. It cannot be specified which type or types of refractory bricks and castables. Because of the different fields of use, the refractory materials used in thermal equipment are also different.

Refractory materials are divided into shaped products and unshaped products in terms of shape and are divided into three categories: ordinary, high-grade, and special-grade in temperature. The chemical properties are divided into acidic, neutral, and alkaline. Refractory insulation bricks and lightweight thermal insulation castables are called thermal insulation or thermal insulation refractory materials. No matter which method is used to define, they are called refractory materials.

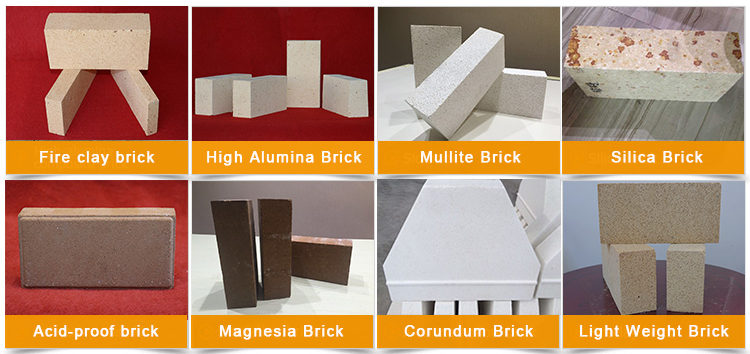

Common acid-resistant bricks, oxide ceramics, refractory insulation bricks, acid-resistant refractory bricks, refractory slurries, refractory castables, lightweight thermal insulation castables, etc. Someone among them raised the question: How many names are there for the above refractory materials? He also cited a similar answer to refractory insulation bricks, also called insulation bricks.

There are many names for different refractory materials, and they are very complicated. And many materials are called differently because of different regions. For people who understand refractory materials and those who do not understand refractory materials, because they have different understandings of the same kind of refractory materials, there may be different names. For example, a common mullite insulation brick. Some people call it K23 fire brick and K28 fire brick; others call it JM23 insulation brick and JM28 insulation brick. There are others called SK32, SK34, SK36, SK37, SK38 refractory bricks, and so on. What they said is the same type of insulation brick products, and there may be slight differences in specific indicators. Therefore, as a refractory manufacturer and seller, no matter what the name of the refractory product is, we first need to confirm with the customer the application furnace type, use position and use temperature of the product that the customer needs. According to the customer’s specific needs, we will provide the customer with refractory materials that meet his thermal furnace equipment production needs.

What are the thermal properties in refractories?

From the point of view of definition, inorganic non-metallic materials with refractoriness greater than 1580 ℃ are called refractory materials. Refractories are part of the material industry, and they are named after they are used in thermal kilns. So what are the thermal properties in refractories?

(1) Thermal expansion

The thermal expansion of refractory materials refers to the length change of the product during heating.

The expansion (or contraction) of refractory materials as the temperature changes in use will seriously affect the size, tightness, and structure of the thermal equipment masonry, and even damage the masonry. In addition, the thermal expansion of refractory materials can also reflect the thermal stress distribution and size of the product after being heated, crystal transformation and phase transformation, the generation of microcracks, and thermal shock resistance.

(2) Thermal conductivity

Under the condition of the unit temperature gradient, the heat flow rate per unit area of the material is defined as the thermal conductivity of the refractory material.

In actual production, the general thermal equipment needs to consider the amount of heat loss after passing through the refractory, and it is necessary to calculate the insulation effect of the insulating refractory. In some muffle furnaces and coke ovens, the partition walls of refractory materials are also required to have higher thermal conductivity. Therefore, the thermal conductivity of refractory materials is one of the key considerations in the design of thermal kiln lining. The pores in the refractory product have a great influence on the thermal conductivity. Within the temperature limit, for the porosity within a certain range, the greater the porosity, the smaller the thermal conductivity, and the better the thermal insulation effect.