· [Abstract] Rotary kiln production and operation requires the use of refractory bricks as kiln lining, and low cement castables are commonly used as linings in the settling chamber. The lining treatment of the cone section depends on the situation. If the discharge opening is too small, no lining is required, otherwise low-cement castables are used and steel fibers are added to improve durability.

Zinc volatilization kilns all use rotary kilns for production and operation. The refractory bricks used for the kiln lining of the rotary kiln need to be made of consistent materials and accurate in size. Only then can the kiln body operate normally and the service life be extended.

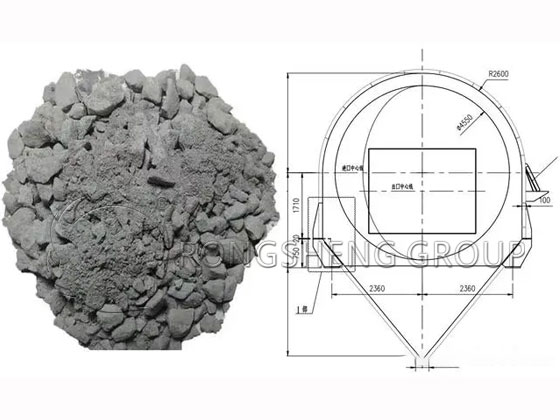

However, the kiln tail smoke chamber, which is the settlement chamber, is lined with clay bricks or low-cement refractory castables. Generally speaking, more low-cement castables are used, while clay bricks are rarely used as linings. The shape of the settling chamber is a cone, with the upper part larger and the lower part smaller, which facilitates the smooth discharge of smoke and dust. Because if this part is designed to be small, or the design of the unloading port is unreasonable, if it is too small, this part will be slapped during daily work to speed up the exhaust of smoke and dust.

At present, according to the situation of the manufacturers, some manufacturers basically do not do any lining treatment on the lower cone section of the settling chamber. The reason is that this area is often patted, and even the lining is patted off. It does nothing, but wastes the castables used and increases costs.

So, should this part be lined with cement refractory castables or bricks? In principle, it is still needed. Low cement castables are used as linings. If steel fibers are added to the castables in the cone section to increase the tensile effect, it will still have a certain effect. And if the discharge opening of the cone section is indeed too small, the use of low-cement castables as lining is indeed not very effective.

In short, whether this part is constructed with low cement castables or nothing is used depends entirely on the working conditions on-site. If the opening of the cone section is too small, there is no need for lining. If the unloading opening is of reasonable size, it is better to use low cement castable to cast the lining.

Rongsheng Refractory Materials Manufacturer has more than ten years of production and sales experience. It has its own unique insights into the design of refractory lining materials, thermal insulation, energy saving, and consumption reduction. We are committed to providing refractory lining solutions to extend the service life of refractory linings, thereby helping companies save production costs. We also have rich experience in various rotary kiln cases. Contact us for more solutions.