Alumina bubble brick for gasifier is a new type of high-temperature insulation material. It is made by smelting and blowing industrial alumina in an electric furnace, and the crystal type is a-Al2O3 microcrystals. The content of AL2O3 in the alumina bubble brick of the gasifier is not less than 98%, the content of SiO2 is not more than 0.5%, and the content of Fe2O3 is not more than 0.2%. The bulk density is 1.3~1.4g/cm3, the apparent porosity is 60%~70%, and the compressive strength is not less than 9.8MPa. The load (0.2MPa) softening temperature is not less than 1700°C, and the thermal conductivity is 0.7~0.8 W/(m.k).

Alumina hollow sphere brick for gasifier is mainly made of alumina hollow spheres, which can be made into products of various shapes, with a maximum operating temperature of 1800°C. The product has high mechanical strength, several times that of general lightweight products, and the bulk density is only one-half of corundum products. It is widely used in high temperature and ultra-high temperature furnaces such as petrochemical industry gasifiers, carbon black industrial reaction furnaces, metallurgical industry induction furnaces, and so on. And achieved a very satisfactory energy-saving effect.

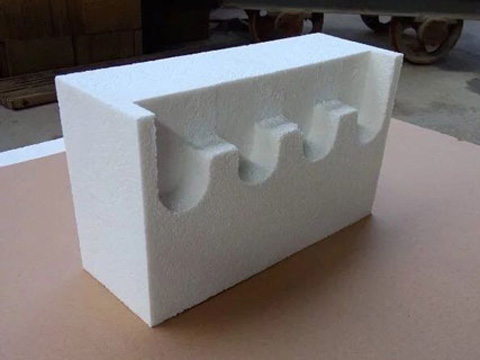

The manufacturing method of alumina bubble brick. First, the alumina raw material is put into the dump-type electric furnace and melted into a liquid state. Then the furnace is poured at a certain angle so that the solution flows out of the casting trough at a certain speed. The liquid flow is blown away by a flat nozzle 60°~90° with the flow stream with a high-speed airflow with a pressure of 0.6-0.8 MPa to form a hollow alumina ball. Then, the alumina hollow spheres, the sintered alumina fine powder, and the binder are compounded in a certain proportion, formed, dried, and fired to obtain alumina hollow sphere bricks.

Alumina bubble brick for gasifier has the following characteristics:

- High temperature and good thermal stability. The reheating line has a small change rate and can be used for longer.

- Optimize the structure to reduce the weight of the furnace body. The alumina bubble brick is only 1.1~1.5g/cm. For the same volume of one cubic meter, the use of alumina bubble bricks can reduce the weight of 1.1-1.9 tons.

- Save materials. To reach the same operating temperature, if alumina bubble bricks are used, 1.1-1.9 tons of heavy bricks can be saved per cubic meter, and 80% of refractory insulation materials can be saved.

- Save energy. Alumina hollow spheres have obvious thermal insulation properties, low thermal conductivity, and can play a very good thermal insulation effect. Reduce heat dissipation and improve thermal efficiency, thereby saving energy.

FAQ1: Will the alumina bubble brick melt at 1700 ℃?

The alumina bubble brick will not melt at 1700 ℃. Alumina hollow sphere is a new type of high-temperature insulation material, which is made by smelting and blowing industrial alumina in an electric furnace, and the crystal type is a-Al2O3 microcrystals. With alumina hollow sphere as the main body, it can be made into products of various shapes, and the maximum use temperature is 1800℃. The product has high mechanical strength, several times that of general lightweight products, and the bulk density is only one-half of corundum products.

FAQ2: What is the general volume ruler of alumina bubble brick?

The high-temperature-resistant materials currently used are heavy bricks with a bulk density of 2.3-3.0g/cm³. The alumina bubble brick is only 1.3~1.5g/cm. For the same volume of one cubic meter, the use of alumina bubble bricks can reduce the weight of 1.1-1.9 tons. The size of alumina bubble brick is generally 230×114×65mm (T3 brick).

If you have a demand for alumina bubble bricks for gasifiers, please contact us. We will provide you with high-quality refractory materials and considerate service.