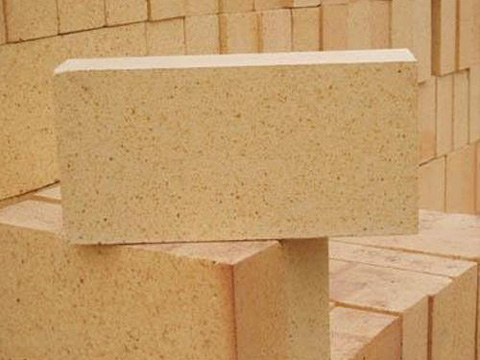

Alumina or high alumina bricks are bricks that are made to provide protection against high heat. These bricks are used in a variety of applications. The most common for these bricks is in glass melting tanks. They are sometimes called fire bricks.

Alumina bricks are also used to line fireplaces, furnaces, and kilns. Besides being resistant to high heat temperatures they can also hold onto their heat for extended periods. This allows them to provide greater efficiency for things like furnaces or fireplaces.

These bricks are made up of about 50 percent alumina. This makes them similar in makeup to fireclay bricks. Fireclay bricks only have about 40 percent alumina. The actual content of the alumina has much to do with the quality of the brick. Alumina bricks do not have porous surfaces so they also expand when they are exposed to high heat temperatures. They can withstand temperatures of over 2900 degrees F.

While they can expand they are not the first choice for high-temperature primary bricks. They are, however, much better suited to back up bricks. The higher the content of the alumina the better off the bricks are for industrial uses. They are also sometimes made of alumina and chrome which makes them perfect for industrial uses that will expose the bricks to both hot and cold temperatures. They can also be resistant to acidic slags.

The alumina in the bricks allows them to have good load bearing capabilities. Again, this is what makes them hold up in even the toughest conditions in industrial uses. For them to be considered high alumina they have to be made mostly of lower alumina silicates or clay.

These bricks have excellent load resistance in industrial uses when they contain some mullite crystals. They can be purchased online from quality manufacturers.