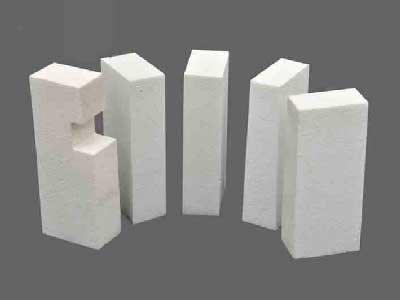

Sillimanite Bricks is a refractory brick with good characteristics prepared by a high temperature firing method or a mud casting method for sillimanite minerals. The sillimanite is calcined at high temperature and converted into mullite and free silica. It is generally produced by high temperature firing and mud casting.

Sillimanite Bricks is a natural high-grade refractory mineral with low thermal expansion rate, resistance to metallurgical slag and various glass liquids, and high temperature wear resistance. Its physical and chemical properties are better than high alumina bricks, the refractoriness is 1770 ~ 1830 ° C, and the load softening starting point is 1500 ~ 1650 °C. It is mainly used for the forming of liquid hole in glass tank kiln, blast furnace lining, furnace throat and ceramic industry kiln furniture. The refractory materials based on natural sillimanite also have these advantages. Therefore, sillimanite refractories are widely used in metallurgy, chemical and building materials industries.

Advantages of Sillimanite Bricks for Sale:

- Good thermal shock resistance

- High dense structure

- Slag corrosion resistance

- Good thermal conductivity

- Good thermal stability

- Heat exchanger

- High structural strength

- Low high temperature creep

Technical Parameter of Sillimanite Bricks for Sale:

| Item/Index | Unit | Sillimanite Bricks | ||

| AK60 | AK60C | S65 | ||

| Raw Material | Andalusite | Andalusite | Sillimanite | |

| Fe2O3 | % | 1 | ≤1.0 | 0.8 |

| Al2O3 | % | 60 | 60 | 65 |

| Thermal Shock Resistance | 120 | 120 | 12 | |

| Apparent Porosity | % | 13 | 15 | 13 |

| Cold Crushing Strength | Mpa | 100 | 100 | 100 |

| Bulk Density | g/cm3 | 2.6 | 2.6 | 2.65 |