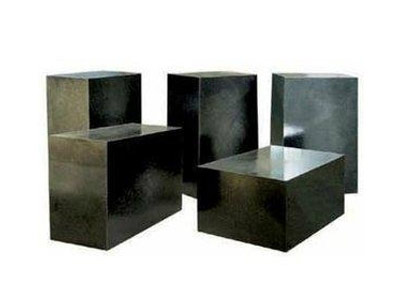

Magnesia carbon brick is a high melting point basic oxide magnesium oxide (melting point 2800 ° C) and a high melting point carbon material which is difficult to be infiltrated by slag as a raw material, and various non-oxide additives are added. A non-burning carbon composite refractory material combined with a carbonaceous binder. Magnesia carbon bricks are mainly used for the lining of converters, AC arc furnaces, DC arc furnaces, and slag lines of ladle.

As a composite refractory material, magnesia carbon brick effectively utilizes the strong slag corrosion resistance of magnesia and the high thermal conductivity and low expansion of carbon, which compensates for the biggest disadvantage of poor flaking resistance of magnesia.

Main features: good high temperature resistance, strong slag resistance, good thermal shock resistance and low temperature creep.

Technical Parameter of Magnesia Alumina Carbon Brick:

| Product | MgO (%) in DBM, | Al2O3 (%) | Fixed C (%) | A.P (%) | B.D (gm/cm3) | C.C.S (kg/cm2) | Primary Raw Material |

| VRPL AMC- 5 | 10 | 60 | 5 | 7 | 2.95 | 400 | Calcined Bauxite,Fused Magnesia and Graphite |

| VRPL AMC- 10 | 10 | 60 | 8 | 8 | 2.92 | 400 | Calcined Bauxite,Fused Magnesia and Graphite |

| VRPL MALC-10 | 15 | 70 | 7 | 8 | 2.98 | 400 | Brown Fused Alumina,Fused Magnesia and Graphite |