Mullite insulation bricks manufacturers suppliers

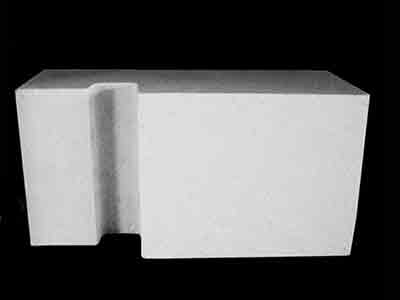

1.Item :Furnace And Kiln Mullite Insulation Brick

2.Classification Temperature:1260 (℃)

3.Bulk Density :0.55-0.60 (g/cm3)

4.Cold Crushing Strength:1.2 (Mpa)

5.Modulus of Rupture:0.9 (Mpa)

6.Reheating Linear Change (%) CT-30 ℃X 8H :1230℃ -0.5

Application of Mullite Insulation Brick

Due to its lightweight and good insulating performance,our mullite insulation bricks has broad use for fire resistance lining in heat side and insulating layers, thus increases energy efficiency greatly. Mullite lightweight bricks are popular in hot blast kiln crown,flame side and bottom parts; glass melting furnace regenerator,ceramic sintering kiln,Petroleum cracking system corners and linings,ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etc.

Characteristics of Mullite Insulation Brick

1.Low thermal conductivity, good heat insulation.

2.Low thermal melting point. Lightweight mullite insulating bricks save heat and energy.

3.Low impurity content,high temperature resistance; higher alumina content ensures good performance.

4.Customized shapes to reduce bricks quantity and cost.

5.Dense,compact and accurate structure,low porosity rate.

6.High loading temperature,corrosion resistance.

Why Choose us?

1.Provide satisfactory service to you.

2.Quality is our culture.

3.With us you money is safe, business is safe.

4.We specialize in refractory products for nearly 20 years.

Light Weight Mullite Brick Parameter:

| Brand | JM23 | JM26 | JM28 | JM30 | |

| Item | |||||

| Max Temperature ( C) | 1260 | 1460 | 1540 | 1700 | |

| Bulk Density (g/cm3) | 0.55-0.60 | 0.8 | 0.89 | 1.03 | |

| Cold Crushing Strength (Mpa) | 1.2 | 1.6 | 2.1 | 2.5 | |

| Modulus of Rupture (Mpa) | 0.9 | 1.4 | 1.6 | 2.1 | |

| Reheating Linear Change (%) | 1230 °C | 1400 °C | 1510 °C | 1620 °C | |

| CT -30 °CX 8H | -0.5 | -0.5 | -0.5 | -0.9 | |

| Thermal Expansion | 0.8 | ||||

| 1100 °C( % ) | 0.5 | 0.7 | 0.8 | ||

| Thermal conductivity (W/m.k ) | 400 °C | 0.14 | 0.27 | 0.32 | 0.41 |

| 600 °C | 0.16 | 0.29 | 0.34 | 0.43 | |

| 800 °C | 0.18 | 0.31 | 0.36 | 0.44 | |

| 1000 °C | 0.2 | 0.33 | 0.38 | 0.45 | |

| Al2O3 % | 37 | 50 | 64 | 72 | |

| Fe2O3 % | 1 | 1 | 1 | 0.5 | |