If you are trying to find alumina silica firebrick for sale, the Internet is one of your best options. With a quick search in your favorite search engine, you can find a lot of different manufacturers who make this specialty product.

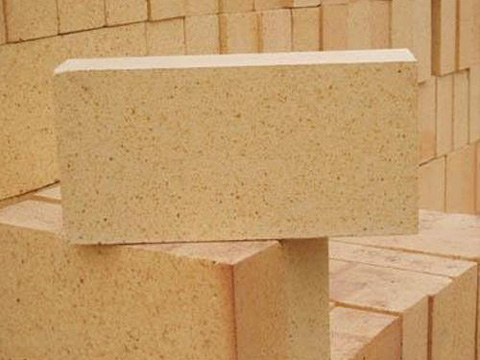

Alumina silica firebrick is designed to withstand high temperatures. It can be used in a variety of high-heat applications, making it a popular choice in quite a few different industries. No matter what type of application you are planning on using it for, you can find a great deal on the exact size and style of fire bricks that you need online.

When you first begin your search, jot down the names of any manufacturers that you find. Most manufacturers will have information on their website about the products that they have available. You should be able to tell at a glance whether or not they have what you need. If they do, write down their contact information so that you can reach out to them to discuss pricing.

Once you have a list of suppliers that carry the type of alumina silica fire brick that you are looking for, you can begin calling around to compare prices. Make sure to clearly describe exactly what type of brick you need as well as the number of bricks that you are planning on ordering. Most manufacturers will offer a volume discount if you order enough bricks. You may be able to save quite a bit of money by placing a large order.

If you are looking for alumina silica firebrick for sale, look no further than the Internet. You can find a lot of different manufacturers online that make and carry this product. By comparing all of your options, you should be able to find a manufacturer who has exactly what you need.

There are three main types of magnesia chrome bricks produced for industrial purposes. Typically these bricks have found great use in environments where pressure and heat resistance are crucial properties to have, for instance in furnaces. Herein are the three types of bricks, their specific properties, and the environment in which they are used.

There are three main types of magnesia chrome bricks produced for industrial purposes. Typically these bricks have found great use in environments where pressure and heat resistance are crucial properties to have, for instance in furnaces. Herein are the three types of bricks, their specific properties, and the environment in which they are used.