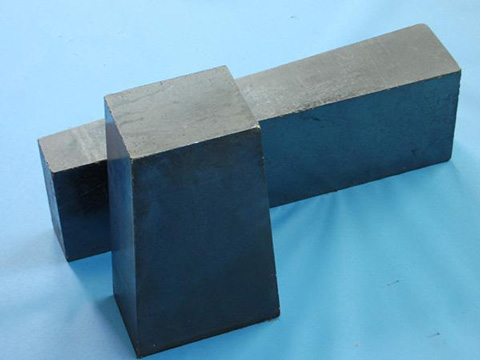

Have you ever wondered exactly what the difference was between carbon bricks and magnesia carbon bricks? If this is a new topic of interest to you, it may be rather hard to understand. In fact, for a topic of this nature, you may not even know where to begin your research. However, with the internet, it is not at all difficult to find out the information you need. By the same token, it can be hard to decide where to begin to find that information. We are going to inform you of three venues that can help you begin your search for information about carbon bricks and magnesia carbon bricks.

Search Engine Friendly

Perhaps one of the best if not most logical steps for finding the information you need about carbon bricks and magnesia carbon bricks is through one of the online search engines. By using either Google, Bing, or one of the others, you sill have no trouble finding exactly what you want. All that is required is searching for the topic in this case, carbon bricks and magnesia carbon bricks, and placing it in quotes. This is going to help bring back all of the most relevant searches first that have that topic contained within it. Additionally, one may also use the power of the internet to find a Wikiguide about this said topic.

Wiki Search

In this case, you will still need to use a search engine, but you are looking for specific information from one of the giant WIki sites. Many times, you will find the information you need through Wikipedia. However, in the case of carbon bricks and magnesia carbon bricks, you may have better luck with a wiki devoted to this topic. To find the information you need, you are going to go to a search engine and type in the following phrase “carbon bricks and magnesia carbon bricks + wiki”. This will bring up a listing of the most relevant wikis that should have the exact information you require. Furthermore, you may want to search through article directories for precise information.

Article Directories

In the past, article directories were a veritable wealth of knowledge. However, they were abused and filled with a lot of spam and poorly written articles. While they are not as popular as they once were, they still contain a great deal of information. In fact, it is possible to find out everything you need to know without ever leaving the directory. Perhaps one of the biggest and best to this day is Ezinearticles. It is well worth a visit to see if there is any information you may be able to find from that site that will help in your research.

All things considered, using one or all of these methods should give you the knowledge that you desire. Take your time and follow through and find a method that you enjoy the most. We hope that these tips will allow you to find out all you need to about carbon bricks and magnesia carbon bricks.