The kiln lining needs to be repaired after wear and tear. According to the wear of the kiln, choose the appropriate repair method. Plastic refractory materials repair, spray refractory materials repair and castable refractory repair can be used.

Refractory is the basic material of high-temperature technology and an important masonry material for kiln lining. In a high-temperature environment, it is in direct contact with slag, charge, decomposition gas, etc., and gradually changes during long-term use. The characteristics of the refractory itself can resist the erosion of slag, chemical, air flow, etc. for a certain period of time. However, over a certain period of time will cause local lining damage, peeling, and other phenomena. At this point, the refractory material needs to be repaired. The refractory material can continue to work through a series of repair operations to ensure the normal operation of the kiln. So, what methods can be used to repair the refractory lining of the kiln?

Converter repair material

Repairing damaged parts of the converter can significantly extend the service life of the converter. With the advancement of spraying technology, converter thermal spraying technology has experienced the direction from high water to low water and no water, that is, from wet and semi-dry to flame spraying.

Blast furnace gunning

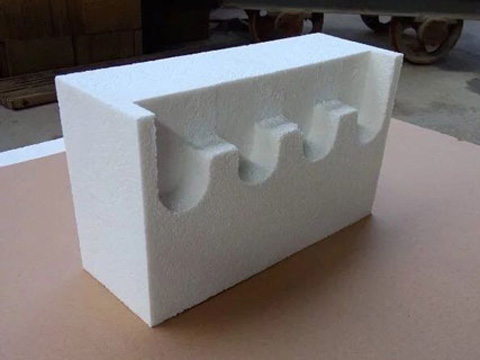

The spray method uses high-pressure air to transport granular refractory materials. Mix with a suitable amount of water in a spray gun and spray on the surface of the repair lining. Attached to a certain thickness (up to several hundred millimeters), replacing the rebuilding of the refractory brick lining.

Repair method of the inner lining of the mixed iron car

Due to its function and operation characteristics, the maintenance of the inner lining of the mixed-rail car is generally divided into major repairs, medium repairs and hot repairs.

Hot blast furnace lining thermal repair technology

As the auxiliary equipment of blast furnace, hot blast stove needs 1-2 generations of blast furnace age. The actual service life of a blast stove is usually determined by the refractory lining of the blast stove system. Refractory linings often have problems during use, and online thermal repair of refractory linings is an effective method to prolong the service life of refractory materials.

Glass Furnace Hot Repair

The traditional furnace thermal repair method has a harsh environment and high labor intensity. Although a great improvement has been made with the use of advanced refractory materials, it is still relatively difficult and burdensome, interfering with normal production. At present, the furnace thermal repair method includes thermal repair methods and thermal oxygen spraying methods.

What are the repair methods for boiler refractory repair?

- The pouring repair method is to pour the unshaped refractory material into the repaired part and combine it with the original lining to resist the erosion of the slag.

- The thermal spraying repair method is to spray the unshaped refractory material to the part that needs to be repaired through the spray gun. And attached to its surface to reach a certain thickness, replacing the rebuilding refractory brick lining. Rebuild the residual brick lining or the furnace lining on the surface of the furnace shell to restore the furnace shape. Compared with other maintenance methods, the major feature of spray repair is that the integrity of the repaired furnace lining is good, and the furnace shape can be reconstructed.

- The injection method is to project the unshaped refractory material to the part that needs to be repaired. The operation is simple and convenient.

- The grouting repair method is also known as the press-in repair method. It uses special press-in equipment to transport specific refractory materials from outside the furnace to designated maintenance parts under certain pressure conditions. So as to achieve the purpose of filling the gap and repairing the furnace lining.

- The digging method is also known as the masonry method, that is, the partially damaged part of the lining is removed first, and then the refractory tiles are used to rebuild the masonry. In this case, the kiln needs to be cooled before construction.

Different lining refractory repair methods are suitable for different furnaces.

- The pouring repair method can be used for repairing any kiln, blast furnace, coke oven, electric furnace, iron tapping point, ladle, etc. after the furnace is stopped.

- Thermal spray repair, which can be used for damage repair of the bottom furnace wall of hot blast furnace, coke oven head, open-hearth, electric furnace, converter, heating furnace, and other furnace linings.

- Spray repair method, mostly used for ladle lining construction.

- The grouting repair method is mostly used for filling between the blast furnace and the furnace wall.

- Excavation repair method, suitable for medium or overhaul of various kilns, blast furnaces, coke ovens, ladle, tundish, etc.

The above is an introduction to the repair method of lining refractory materials. With the development of the refractory industry, the repair methods of refractories have gradually changed. As a refractory manufacturer, Rongsheng Global Refractories has always aimed at kiln refractory solutions, boiler refractory repair, providing users with better refractory materials, and optimizing refractory lining material repair solutions.