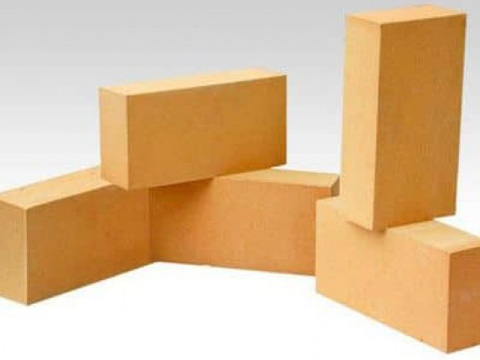

While it may seem that you can use any refractory brick and be fine, the truth is much different. Sadly, different bricks are suitable for different projects, and using the wrong one may cost you money, cause accidents, or simply cause you to not generate as much heat. When you are working with something that requires a large amount of fuel, this can make or break your operation. Many companies fail each and every year because they don’t do their research and assume that the materials they have picked out will do the right job.

Looking up the different classifications and uses of the alumina refractory bricks you want to buy, or any bricks that you are planning to use, is a simple step that could save you thousands. This information is usually readily available from the manufacturer and will give you a better chance at making an informed decision. If you cannot find the information on the manufacturers website, you should contact them and discuss the project that you are planning to undertake. They should be able to tell you what is recommended and may even be able to help you figure out how much you need to buy.

If you still don’t understand what you need to use, there are also online communities available that can help you make the right decision. Find a community that revolves around the industry you are looking to outfit yourself with bricks for and ask what they use and why. Most of the time they will be more than happy to answer as people who fail within the industry and don’t deliver on the things that they promise, actually make them look bad as well.

Good luck figuring out the proper classifications and uses of the alumina refractory bricks for your personal or business projects.