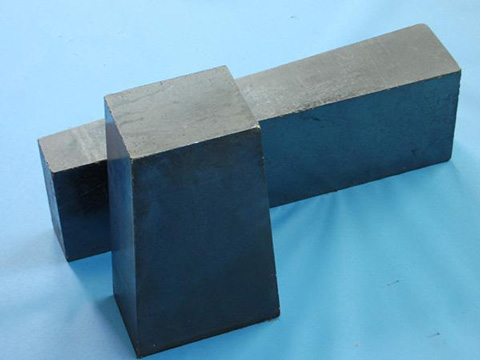

The checker brick is used for its surface and the value it provides in hotter temperatures. Imagine putting a regular brick in a hot furnace. What would happen to the brick? Would it last or would it fall apart as soon as the heat touched it? In most cases, the brick would fall apart, and that is the reason those options are not utilized. Instead, the goal is to use a checker brick that can handle the heat and maximize what it is there to do.

Here are the key benefits of the checker brick.

1) Handles Heat

The key benefit and the reason you are going to get these bricks has a lot to do with heat.

You are going to be able to manage the heat efficiently and start to see quality results as time goes on. It will not wilt under pressure.

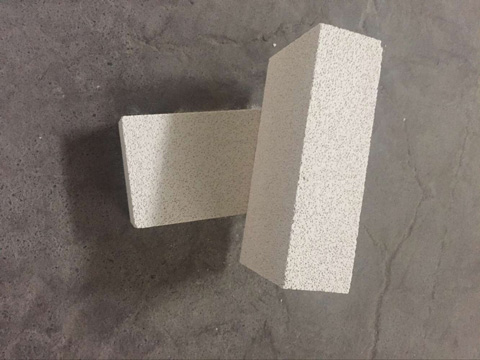

2) Easy To Install With Furnace

The one thing people are going to wonder about is how long will it take to install the bricks. This is not a concern at all with the checker brick since it will be able to install into place within minutes. Most people can have their furnace running in seconds.

Yes, it is that easy to get things into place.

You are going to adore the power of checker bricks and how they can turn things around in a factory setting. These are the ultimate bricks for a reason and do a fantastic job.

Go with these checker bricks and feel comfortable with how long they are going to last and how well they are going to handle heat. There isn’t a better option on the market for those who are setting up a furnace and want to put up a stable lining to protect it.