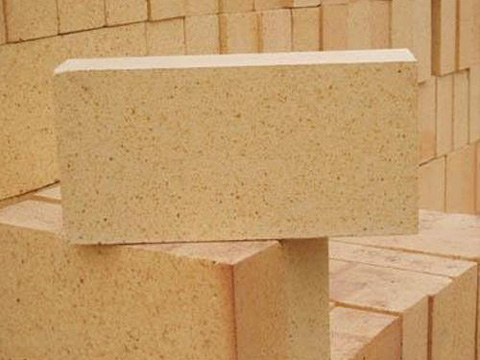

High alumina cement is used when you need to create forms that can handle high heat, like the linings of furnaces and other things that have to handle very high temperatures. You can mold the cement shapes or trowel or pour it into place so you can use it in your furnaces or kilns.

High alumina cement is high performance and will perform well once you get it into shape. After all the moisture is dry the cement will be ready for use. You can use it in multiple ways and there are so many purposes for this cement that you might be surprised at all the ways you can use it.

Alumina cement is very strong and it is going to last for a long time once you get it into place. The cement is very useful and it also has an affordable price. You can find it for low prices when you shop around and you can easily use it by mixing it with water. You can’t use regular cement for high-temperature applications but you can use alumina cement for very high-temperature applications.

When you use this type of cement, you don’t have to worry about it cracking or breaking down and it is going to provide you with superior performance that you can count on every time that you use it. The cement is very easy to work with and you can get going with it right away and put it to work immediately to construct your furnaces.

Buying this cement online is the best value and make sure that you compare prices from a few different cement manufacturers so you are certain of getting the best price. This cement is going to be a great asset when you are repairing kilns or furnaces.