Indexes of Graphite Electrodes

1.Resistivity < 7 Ω 2.Ash Content < 0.3% 3.Bulk Density > 1.6g/cm3 4.Bending Strength> 9.8MPa 5.Young’s Modulus: 9.0-13.0

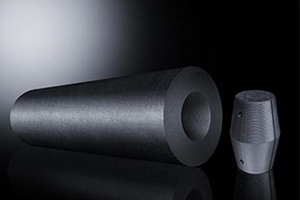

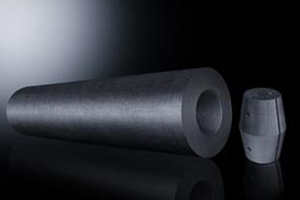

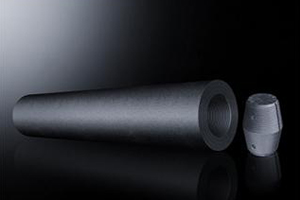

Description of Graphite Electrodes

The graphite electrode is mainly made of petroleum coke and needle coke, and the coal bitumen is used as a binder. It is made by calcination, compounding, kneading, pressing, roasting, graphitization and machining. In the production process, it has the following characteristics: long production cycle, high energy consumption, and many production processes. According to its quality, it can be divided into ordinary power graphite electrode, high power graphite electrode and ultra high power graphite electrode.

Features of Graphite Electrodes

1.Low ash

2.Good oxidation resistance

3.Good electrical conductivity

4.Easilyand fast to be produced

5.Compact structure and mechanical strength

6.Low resistivity

7.Low graphite loss

8.High mechanical strength

9.High discharge removal rate

Graphite Electrodes Varieties

For Direct Current Furnaces (Size: 22-32 inches):

Electrodes for Dc furnaces, which require 1 column of graphite electrodes. High maximum current density. The maximum diameter of these electrodes is 32 inches (801 mm).

For Alternating Current Furnaces (Size: 16-28 inches):

Alternating current furnaces require 3 columns of graphite electrodes. They mostly use 20-28 inch electrodes, the standard size in electric furnaces.

For Refining Furnaces (Size: 10-18 inches):

These electrodes are for refining materials like molten steel. Refining Furnaces have a smaller capacity than DC Furnaces.

Rongsheng Refractory

Rongsheng’s range of top quality graphite electrodes are produced using some of the world’s finest needle cokes and production techniques. This coupled with machining, testing, packing and distribution from our dedicated facilities, ensures our product and service remains consistent, cost effective and reliable. Please Contact us!

Indexes of Graphite Electrodes

Physical and Chemical Indexes:

| Items | Unit | Op Graphite Electrode | Hp Graphite Electrode | Uhp Graphite Electrode | |

| Resistivity < | Electrode | Ω | 9.0 | 7.0 | 6.0 |

| Nipple | 7.5 | 5.5 | 5.0 | ||

| Bending

Strength > |

Electrode | Mpa | 9.8 | 10.5 | 10.5 |

| Nipple | 13.0 | 14.0 | 16.0 | ||

| Elasticity Modulus > | Electrode | Gpa | 9.3 | 12.0 | 14.0 |

| Nipple | 13.7 | 14.0 | 15.0 | ||

| Density > | Electrode | g/cm3 | 1.52 | 1.60 | 1.65 |

| Nipple | 1.68 | 1.70 | 1.72 | ||

| Thermal Expansion < | Electrode | x10-6m/℃ | 2.9 | 2.4 | 1.5 |

| Nipple | 2.7 | 2.2 | 1.4 | ||

| Ash< | % | 0.3 | 0.3 | 0.3 | |

Size/Weight Chart:

| Diameter x length (inch) | Pole diameter (mm) | Pole length (mm) | Pole weight (reference value) (kg) |

| 14×60 | 352~357 | 1400~1550 | 253 |

| 14×72 | 1700~1875 | 304 | |

| 14×96 | 2275~2475 | 406 | |

| 16×60 | 403~409 | 1400~1550 | 334 |

| 16×72 | 1700~1875 | 395 | |

| 16×96 | 2275~2475 | 532 | |

| 18×72 | 454~460 | 1700~1875 | 486 |

| 18×96 | 2275~2475 | 665 | |

| 18×110 | 2550~2850 | 766 | |

| 20×72 | 505~511 | 1700~1875 | 614 |

| 20×84 | 1975~2175 | 715 | |

| 20×96 | 2275~2475 | 824 | |

| 20×110 | 2550~2850 | 927 | |

| 22×84 | 556~562 | 1975~2175 | 873 |

| 22×96 | 2275~2475 | 995 | |

| 24×84 | 607~613 | 1975~2175 | 1040 |

| 24×96 | 2275~2475 | 1190 | |

| 24×110 | 2550~2850 | 1340 | |

| 26×110 | 657~663 | 2550~2850 | 1580 |

| 28×110 | 708~714 | 2550~2850 | 1830 |

| 30×110 | 759~765 | 2550~2850 | 2060 |

| 32×110 | 810~816 | 2550~2850 | 2450 |