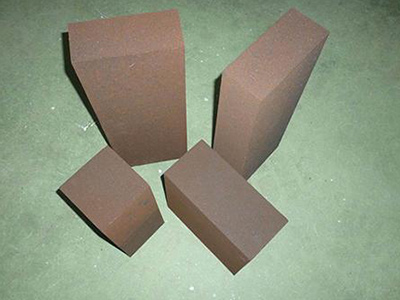

Performance of Magnesia Chrome Bricks

1.MgO Content: Over 75% 2.RUL(T6): Over 1700℃ 3.CCS: Over 50MPa 4.Strong Resistance To Corrosion

Description of Magnesia Chrome Bricks

The main raw materials for the manufacture of magnesia-chrome bricks are sintered magnesia and chromite, and the purity of the magnesia raw material need to be as high as possible. Magnesia chrome bricks are mainly used in the metallurgical industry, such as the roofs of open hearths and electric furnaces, refining furnaces and various non-ferrous metal smelting furnaces. In addition, magnesia-chrome bricks are also used in firing zones of cement rotary kiln and regenerators of glass kiln.

Features of Magnesia Chrome Bricks

1. Refractoriness up to 1800 ° C

2. High temperature strength

3. Strong resistance to alkaline slag

4. Excellent thermal stability

5. Certain adaptability to acid slag

Types of Magnesia Chrome Bricks

According to the different production methods and main raw materials, magnesia-chrome bricks can be divided into sintered magnesia-chrome bricks, direct-bonded magnesia-chrome bricks, special direct-coupled magnesia-chrome bricks, and fuse-rebonded magnesia-chrome bricks.

|

Item |

RS-MGe |

RS-DBMGe | RS-TZMGe |

RS-FRMGe |

| MgO (%) ≥ |

50 |

60 | 55 |

65 |

| SiO2 (%) ≤ |

/ |

2.5 | 2.0 |

1.4 |

| Cr2O3 (%) ≥ |

18 |

16 | 18 |

20 |

| Apparent Porosity % ≤ |

22 |

18 | 16 |

16 |

| Bulk Density g/cm3 ≥ |

3.0 |

3.10 | 3.25 |

3.10 |

| Cold Crushing Strength Mpa ≥ |

30 |

40 | 50 |

50 |

| 0.2Mpa Refractoriness Under Load T0.6 ℃ ≥ |

1550 |

1650 | 1650 |

1700 |