Performance of Graphite Electrodes

1.Low Resistivity 2.Good Electrical Conductivity 3.Good Anti-oxidation 4.High Mechanical Strength 5.Easily To Be Produced

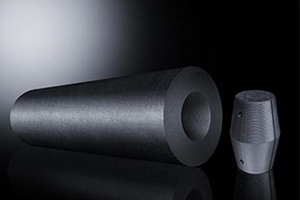

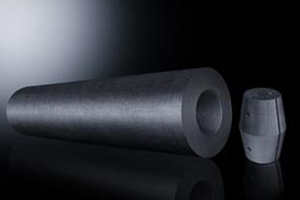

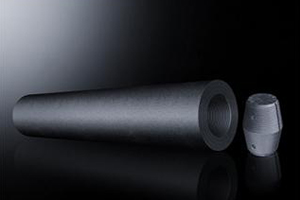

Description of Graphite Electrodes

The graphite electrode is mainly made of petroleum coke and needle coke, and the coal bitumen is used as a binder. It is made by calcination, compounding, kneading, pressing, roasting, graphitization and machining. According to its quality, it can be divided into ordinary power graphite electrode, high power graphite electrode and ultra high power graphite electrode.

Graphite Electrodes Varieties

For Direct Current Furnaces (Size: 22-32 inches):

Electrodes for Dc furnaces, which require 1 column of graphite electrodes. High maximum current density. The maximum diameter of these electrodes is 32 inches (801 mm).

For Alternating Current Furnaces (Size: 16-28 inches):

Alternating current furnaces require 3 columns of graphite electrodes. They mostly use 20-28 inch electrodes, the standard size in electric furnaces.

For Refining Furnaces (Size: 10-18 inches):

These electrodes are for refining materials like molten steel. Refining Furnaces have a smaller capacity than DC Furnaces.

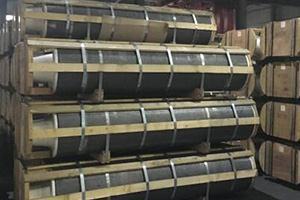

Transportation of Graphite Electrodes

During the transportation of exporting, graphite electrodes are usually packaged in wooden cages, the nipples are packaged in wooden boxes. Sometimes, according to the requirements of the users, the electrodes and nipples will be packaged after connecting. The lining is made of waterproof and dust-proof plastic cloth, and the outer is fastened by steel belts, which is beautiful and firm.

Our products have been sold to domestic and international areas, and have won praises from customers for graphite electrodes price, quality and after-sales service. Around the world, Rongsheng® works closely with trucking companies that understand delivery requirements and provide timely and reliable service at a competitive price. We also work with ocean carriers that have the specialized equipment required for secure transport of our graphite electrodes and frequent sailing schedules to multiple destinations. Together, we meet customers’ schedules and deliver on time, 99% of the time.

Indexes of Graphite Electrodes

| Items | Unit | Rp Graphite Electrode | Hp Graphite Electrode | Uhp Graphite Electrode | |

| Resistivity < | Electrode | Ω | 9.0 | 7.0 | 6.0 |

| Nipple | 7.5 | 5.5 | 5.0 | ||

|

Bending Strength > |

Electrode | Mpa | 9.8 | 10.5 | 10.5 |

| Nipple | 13.0 | 14.0 | 16.0 | ||

| Elasticity Modulus > | Electrode | Gpa | 9.3 | 12.0 | 14.0 |

| Nipple | 13.7 | 14.0 | 15.0 | ||

| Density > | Electrode | g/cm3 | 1.52 | 1.60 | 1.65 |

| Nipple | 1.68 | 1.70 | 1.72 | ||

| Thermal Expansion < | Electrode | x10-6m/℃ | 2.9 | 2.4 | 1.5 |

| Nipple | 2.7 | 2.2 | 1.4 | ||

| Ash< | % | 0.3 | 0.3 | 0.3 | |

Size/Weight Chart:

| Diameter x length (inch) | Pole diameter (mm) | Pole length (mm) | Pole weight (reference value) (kg) |

| 14×60 | 352~357 | 1400~1550 | 253 |

| 14×72 | 1700~1875 | 304 | |

| 14×96 | 2275~2475 | 406 | |

| 16×60 | 403~409 | 1400~1550 | 334 |

| 16×72 | 1700~1875 | 395 | |

| 16×96 | 2275~2475 | 532 | |

| 18×72 | 454~460 | 1700~1875 | 486 |

| 18×96 | 2275~2475 | 665 | |

| 18×110 | 2550~2850 | 766 | |

| 20×72 | 505~511 | 1700~1875 | 614 |

| 20×84 | 1975~2175 | 715 | |

| 20×96 | 2275~2475 | 824 | |

| 20×110 | 2550~2850 | 927 | |

| 22×84 | 556~562 | 1975~2175 | 873 |

| 22×96 | 2275~2475 | 995 | |

| 24×84 | 607~613 | 1975~2175 | 1040 |

| 24×96 | 2275~2475 | 1190 | |

| 24×110 | 2550~2850 | 1340 | |

| 26×110 | 657~663 | 2550~2850 | 1580 |

| 28×110 | 708~714 | 2550~2850 | 1830 |

| 30×110 | 759~765 | 2550~2850 | 2060 |

| 32×110 | 810~816 | 2550~2850 | 2450 |