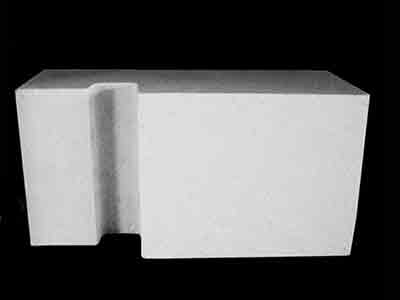

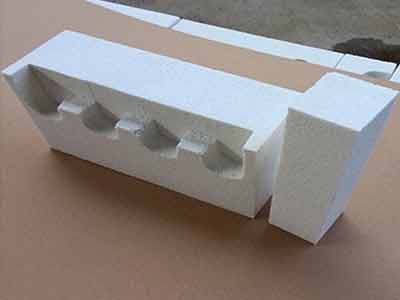

Alumina Bubble Brick Used in Precision Casting Furnace

♦Classification temperature (°C) :1800°C/3270°F

♦Cold Crushing Strength :≥12

♦AL2O3(%) :≥91

♦SiO2(%) :≤15

♦Fe2O3(%) :≤2

Alumina Bubble Bricks are for applications up to 1800°C/3270°F. These bricks have excellent insulating properties and high hot strengths. Bubble alumina bricks are made with tiny hollow insulating spheres made from high-purity alumina (also called bubble alumina). Alumina does not exhibit high thermal conductivity, and when in the form of hollow spheres, its thermal conductivity is additionally reduced. Both properties make Bubble Alumina brick an excellent insulating material that can withstand exceptionally high temperatures.

Features of Alumina Bubble Brick:

1. High purity;

2.High mechanical strength

3.Low thermal conductivity

4.Good stability

5. Mainly apply to the insulation layer of coal-water slurry gasifier

6. Excellent thermal insulation

7. Long service life

8. High compressive strength

9. Competitive price

Applications

High-purity alumina hollow insulating spheres are designed to withstand high temperatures and demanding environments.

The insulating firebrick (IFB) that contains high-alumina bubbles are often used as the working lining in ceramic kilns, backup linings in gasifiers for coal and petroleum coke, gas/oil (with heavy residue feed stock), and industrial waste. These IFBs are also used in hazardous waste and fluorine processing incinerators, hydrogen generators, auto thermal reactors for methanol production, and ammonia reformers.

If you want to know which refractory is suit for you ,please Click Here to contact us, we will work out a detailed solution for you.

Application of Alumina Bubble Brick:

| Item | Ultra Purity Bubble

Alumina Brick |

Bubble Alumina Brick | |

| HAB-99 | SAB-99 | SAB-90 | |

| Max service temperture | 1800 | 1800 | 1800 |

| Al2O3,% | ≥99.3 | ≥99 | ≥90 |

| SiO2,% | ≤0.15 | ≤0.3 | ≤9 |

| Fe2O3,% | ≤0.1 | ≤0.2 | ≤0.2 |

| Bulk density | 1.5-1.8 | 1.5-1.8 | 1.4-1.9 |

| Cold crushing strength | ≥12 | ≥15 | ≥18 |

| Refractoriness under load 0.1MPa,0.6% | ≥1700 | ≥1700 | ≥1700 |

| Reheating linear change 1600℃*8h | -0.25 | -0.25 | ±0.2 |

| Room temp to 1300℃ Thermal

expansion coefficient |

8.6 | 8.6 | 8 |

| Thermal Conductivity Average 800℃ | 0.75 | 0.75 | 0.6 |