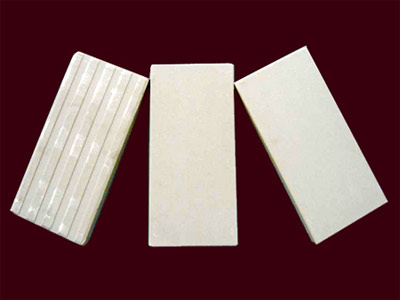

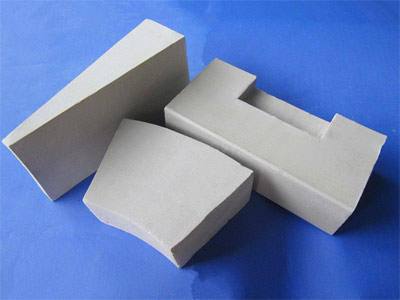

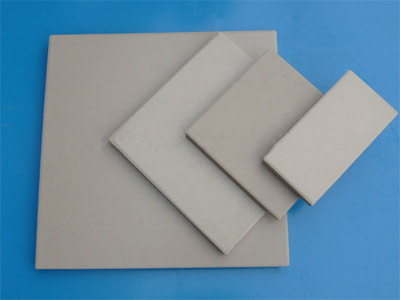

Acid proof brick (also known as acid-resistant ceramic tiles, acid-resistant porcelain plates, acid-resistant and alkali-resistant bricks is a kind of anti-corrosion and acid-proof material) take quartz, feldspar and clay as the main raw materials. It has high acid resistance, low water absorption, low oxidation rate at room temperature, and is not easily contaminated by medium.

The component of acid-resistant brick is silica, which forms a large amount of mullite under high temperature roasting, which is a substance with high acid resistance. Since the acid-resistant brick has a compact structure and low water absorption, it can withstand any temperature at normal temperature. Alkal medium of concentrated concentration, but not resistant to high temperature. Acid-resistant brick contains more than 70% of silica and is sintered. It is widely used in the chemical industry for acid-groove, acid well, acid storage and acid carrier. The big impacted ground.

Technical Parameter of Acid Proof Brick:

| Item | Acid Proof Brick | ||

| Bulk Density | g/cm3 | 2.31-2.4 | GB/T8488-2001 |

| Water Absorption Rate | % | ≤2.0 | GB/T8488-2001 |

| Acid Resistance | % | ≥99.8 | GB/T8488-2001 |

| Anti Bending Strength | Mpa | ≥58.8 | GB/T8488-2001 |

| Anti Compressive Strength | Mpa | ≥120 | GB/T8488-2001 |

| Thermal Stability | 130℃-20℃ | Not cracking | GB/T8488-2001 |